Benefit 1: Total respect for the Astrié invention

The system invented by the Astrié brothers allows micrometric adjustment of the distance between the grinding wheels. This is what makes the quality and finesse of the grinding possible.

The breakthrough came with the design and development of an oscillating system for the rotating grinding wheel. An ingenious combination of two springs makes it possible to control the upward force exerted by the grinding wheel and to precisely adjust the gap between the two wheels.

‘The progress I’ve made allows me to perfectly control the distance between the grinding wheels. Added to this is the grinding of the working surfaces, instead of the traditional pitting that breaks the sound. This makes it possible to obtain calibrated, type 80 flour in a single pass, with no visible bran. A result impossible to achieve with cylinders as well as with old mills.

At Astréia, we fully respect the invention of the Astrié brothers.

Benefit 2: Quality and fineness of grind

The quality and finesse of the milling: that’s our strength. With an extraction rate of 80% in a single pass, the flour is neither heated nor oxidised.

The flour is made up of the whole wheat seed. In fact, the milling system allows you to unroll and finely grind the flour. As a result, your flour will contain the germ of the seed and all its kernels.

The only thing that will be extracted is the husk of the wheat grain, i.e. the bran.

You can, of course, choose to adjust the spacing between the millstones to obtain the optimum spacing for grinding your grain.

Benefit 3: 80% extraction rate in 1 pass

On any other mill, several passes between the millstones or cylinders are necessary to obtain such a high extraction rate (80% in a single pass).

Benefit 4: Output of 15 kilos / hour

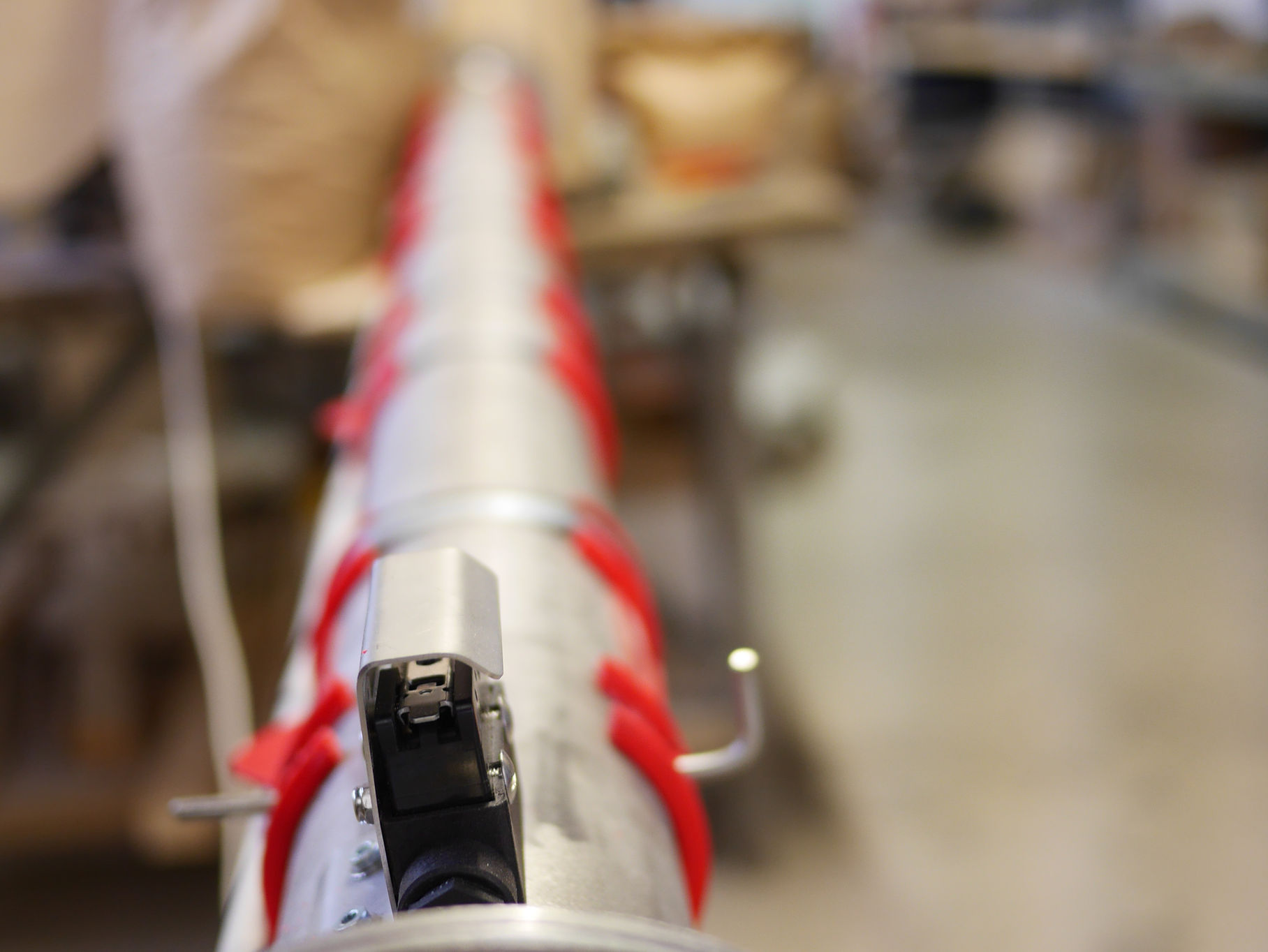

Our stone flour mill is made in our workshop by Yannis, and the millstone is 50 cm in diameter. This means you’ll get an output of 15 kilos per hour. If you leave the mill running all day, you’ll have over 100 kilos of flour.

You can also add an automatic bagging option to leave the mill running for 24 hours.

The bagging ramp will then bag your flour directly, allowing you to produce over 1,500 kilos of flour over 5 days!

Benefit 5: Preserved nutritional qualities

The Astréïa mill, of the Astrié type, produces fine, nutritious flour that is a true reflection of your wheat or cereal. A local flour.

Benefit 6: Our lead times

Our manufacturing lead times are 2 to 3 months maximum from receipt of the deposit cheque.

Benefit 7: A free quote in 48 hours!

We know that getting a free quote quickly is important to you, so as soon as you fill in the quote request form on our site, we do everything we can to ensure that you receive it by email within 48 hours. Make sure you check your emails