What types of electric flour mills are on the market?

- cylinder mill

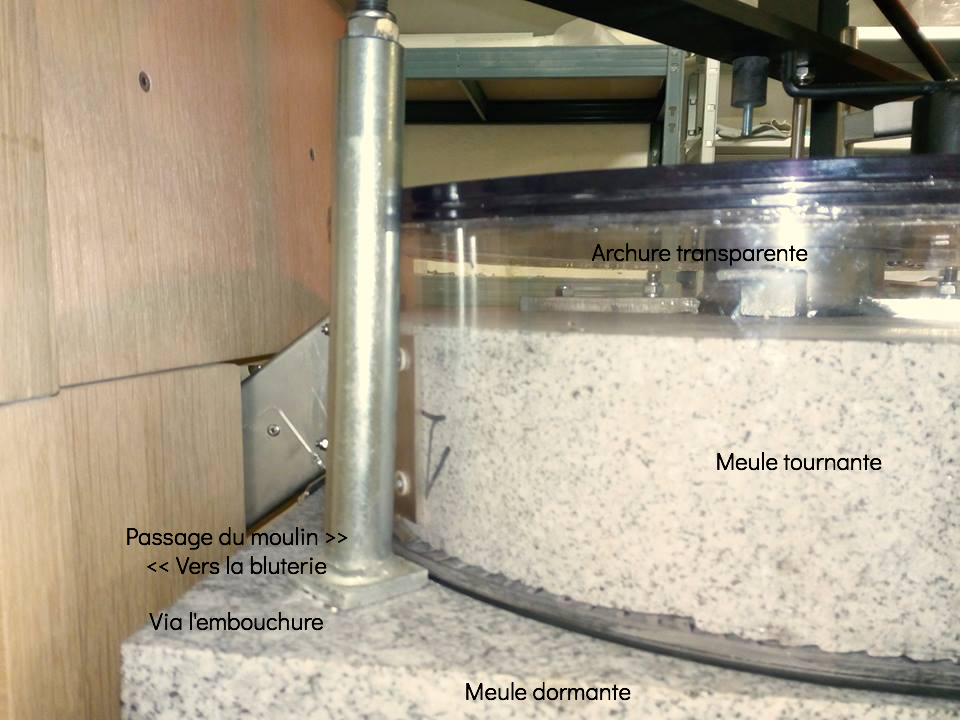

- The Astrié mill differs from other stone mills in that it does not crush the grain, but rather unwinds it.

- stone mill

How much flour do you need?

Traditional stone flour mills were replaced by cylinder mills in the course of industrialisation: cylinder mills are more efficient, so you get more kilos of flour per hour.

What quality of flour would you like to work with?

Stone mills have evolved, providing an interesting yield for a farm looking to make the most of its know-how.

Note: it is still necessary to make several passes to crush the grain. The cereal is therefore generally heated, less so than in a cylinder mill of course, but it also loses some of its nutritional value with each pass.

The Astrié mill, the ‘TOP’ electric stone mill

André and Pierre Astrié realised that the quality of flour from a stone mill was slightly superior, so they set out to improve the system for crushing the grain.

In a traditional stone mill, the grain remains crushed, heated and oxidised. How could this be avoided?

So the Astrié brothers set out to avoid crushing the seed, so as to preserve the whole germ. And they succeeded thanks to an oscillating system: simple and ingenious.

What are the advantages of an electric flour mill like the Moulin Astrié?

The grain is no longer crushed by the weight of the millstones, but unrolled.

They have invented a micrometric adjustment which, depending on the cereal chosen, allows the grain to be unrolled and no longer crushed.

So what if you unroll the seed instead of crushing it?

• The seed germ is preserved in its entirety, allowing :

- proteins

- mineral salts

- vitamin B

• the seed is never heated, since the extraction rate is 80% in a single pass

• all nutritional requirements are maintained

• flour is easier to digest

• the flour obtained is a local flour

Astrié flour: high added value

The flour obtained with an Astrié electric flour mill is therefore a local flour: more nutritious, of higher quality and therefore providing added value for the end consumer or the farmer-baker.

An Astrié agricultural electric flour mill: ‘alicament’ flour

If we had to sum up this article, we’d say that the Astrié agricultural grain mill :

adds value to the processed product: bread, pasta, biscuits, etc.

unwinds the grain without crushing it (so the bran is not mixed)

respects the grain without heating it

preserves the properties of the grain

has an extraction rate of 80% in a single pass

adds value to your cereal

To find out more about the Astrié mill, read our article ‘8 things you need to know about the Astrié mill’.