The Astrié mill is different in that it doesn’t crush the grain, but unrolls it.

The amount of flour

During the industrialisation of the West, stone mills were replaced by cylinder mills to cope with the increased demand for flour. That’s why cylinder mills are more efficient. The system produces more flour per hour.

Flour quality

Stone mills have come a long way, making it possible to refine the rotation of the millstones for optimum crushing in as few passes as possible.

That said, it is still necessary to make several passes for the cereal to be crushed in a traditional stone mill. The cereal is therefore generally heated, losing its nutritional value with each pass.

The Astrié mill, the ‘must’ of stone mills

It was here that André and Pierre Astrié made a real breakthrough: based on the observation that the quality of flour from a stone mill was slightly better, they set out to improve the system for crushing the grain.

In a stone mill, the seed remains crushed, heated and oxidised.

The seed is crushed by the weight of the grinding wheel. So they decided not to ‘crush’ the seed but to unroll it so as to preserve the whole germ. The idea is to remove only the ‘bran’ (the husk of the wheat kernel) and then retain the whole kernel for a flour that is easy to digest, healthy and with high added value.

The difference between a traditional stone mill and an Astrié stone mill

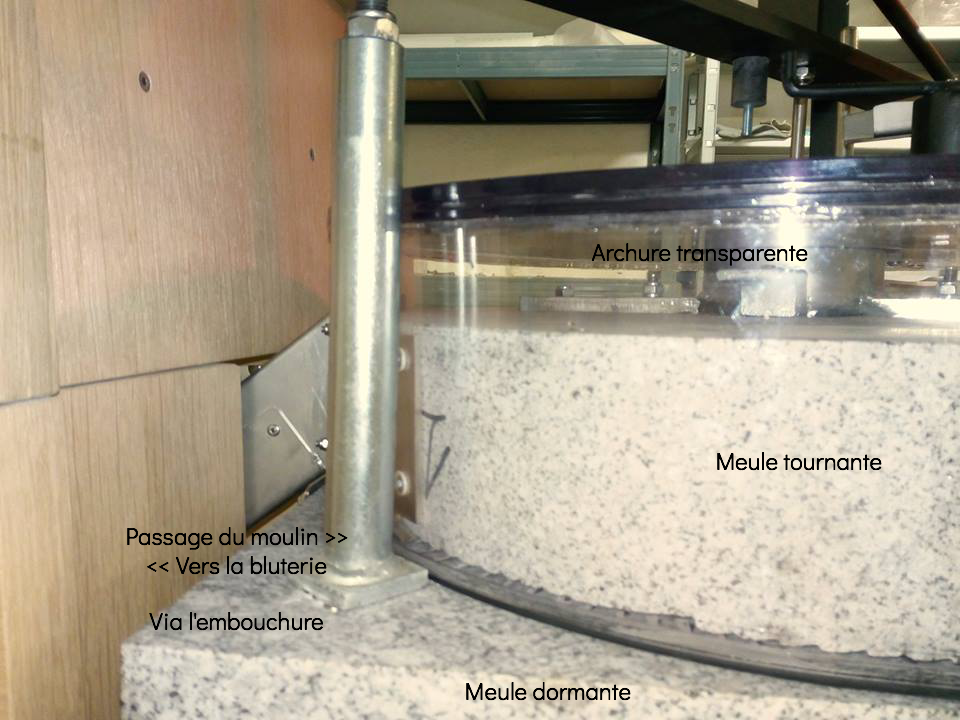

With a stone mill of the ‘Moulin Astrié’ type: the seed is no longer crushed by the weight of the millstones, but is unrolled.

The rotating grindstone unrolls the cereal seeds in its grooves on the stationary grindstone. It is not the weight of the millstone that crushes the seed, but its rotation that unrolls the grain to extract the husk and preserve the entire germ.

They have invented a micrometric adjustment system which, depending on the cereal chosen, allows the seed to be unrolled and no longer crushed.

What difference does it make to unroll the seed instead of crushing it?

The seed germ is preserved in its entirety, allowing :

- proteins

- minerals

- vitamin B

• the seed is never heated, since the extraction rate is 80% in a single pass

• all nutritional requirements are maintained

• flour is easier to digest

• the flour obtained is a local flour

• all cereals can be crushed as long as they are perfectly dry

The local flour obtained is of great added value

The flour obtained with an Astrié mill is therefore a local flour: more nutritious, of higher quality and therefore providing added value for the end consumer or the farmer-baker.

Depending on the sieve you choose for your mill and the grain you crush (wheat, buckwheat, rye, barley, etc.), you can obtain different types of flour. With the sieve included in the mill offered by Astréïa, your flour will be T80.

Want to know which seeds you can unroll with an Astrié stone mill?

It’s even possible to make ‘gluten-free’ flour in an Astrié-type stone mill, to find out how: Read our full article ‘How do I make gluten-free flour with my Astrié mill?’

Moulin Astrié: for the health of consumers

If we had to sum up this article, we would say that the Astrié mill :

- unrolls the grain rather than crushing it

- adds value to the processed product or cereal

- does not heat up the cereal through multiple passes

- preserves all the nutritional qualities of the crushed cereal

- has an extraction rate of 80% in a single pass

- produces a local flour

To find out more about the Astrié mill, read our article ‘8 things you need to know about the Astrié mill’.