Why are we talking about an Astrié flour mill and not a stone millstone flour mill?

The Astrié mill falls into the category of stone mills, and is therefore a specific type of stone mill.

André and Pierre Astrié are the inventors of the famous ‘Moulin Astrié’, and gave their discovery their name. That’s why the mill is called that.

What did the Astrié brothers find for the mill?

The progress they have made compared with a conventional stone mill means that the distance between the wheels can be perfectly controlled. We call this micrometric adjustment of the grinding wheels.

With an Astrié mill, the grain is no longer crushed between the millstones by the weight of the stone, but is unrolled between the millstones to preserve the germ and remove only the husk, i.e. the bran. All the cereal’s nutrients are retained.

The essential nutrients are therefore perfectly preserved in your flour.e.

This setting lets you choose the type of flour you want.

It also lets you choose the cereal you want to unroll.

(Article ‘Everything you need to know about the Astrié mill’)

A difference in the millstones

Old stone mills often use soft stones or millstones that need to be assembled, in particular with steel. The Astrié mill, on the other hand, uses granite from Sidobre (Tarn), which, once cut to a very precise shape, is extremely durable, reliable and of high quality.

Stay alert!

An Astrié mill using a millstone without Granit du Sidobre would therefore no longer be an Astrié mill, but a mill with a classic stone millstone, so be careful when you do your research.

And the weight of the millstones? Thanks to André and Pierre Astrié’s work on improving the classic stone mill process, the size of the millstones and therefore their weight has been reduced. The complete mill we sell weighs around 200kg (mill + hopper + sieving machine).

A difference in rotation speed

Caution!

As you know, to preserve all the qualities of the cereal, the grain must not overheat between the millstones.

That’s why the Astrié mill has a rather slow rotating grinding wheel. Above a certain speed, the seed is heated, oxidised and drastically loses its nutritional qualities.

That’s why an Astrié mill differs from a stone mill: the output is lower, so you can continually work on the quality of the flour you produce.

At Astreia, we don’t take any risks about condensation or clogged grooves (which would force you to dismantle the millstones to clean them): with an Astrié mill, we favour a high added-value grind rather than a high yield. The output of the Astrié mill we sell at Astréïa is around 15 kilos of flour/hour for wheat milling.

What is the difference between the flour produced by a stone mill and that produced by an Astrié mill?

The flour obtained from an Astrié mill contains all the nutritional content of the cereal. The wheat germ and all its vitamins are perfectly preserved during the process.

So the flour is nutritious and easy to digest!

This result is impossible to achieve with cylinders as it is with other old stone mills.

With a traditional stone mill, the grain is crushed; it’s the weight of the millstone that crushes the grain. With an Astrié mill, the grain is not crushed because you adjust the distance between the millstones. The grain is unrolled to preserve the germ and only the husk, i.e. the bran, is removed.

What’s the difference in terms of work organisation?

As the grinding wheels rotate at a slower speed, you can leave the mill running on its own while you devote yourself to your other activities. It’s even possible to power the mill continuously so that it works 24 hours a day.

At Astréïa, depending on the layout of your space, we can advise you on how to keep the hopper fed even when you’re away.

Ask us for advice, it’s our job!

But that’s not all! A difference in the hopper

Our mill is equipped with a sensor that stops the mill immediately when the hopper is empty.

You can store around 25 kilos of grain in the hopper.

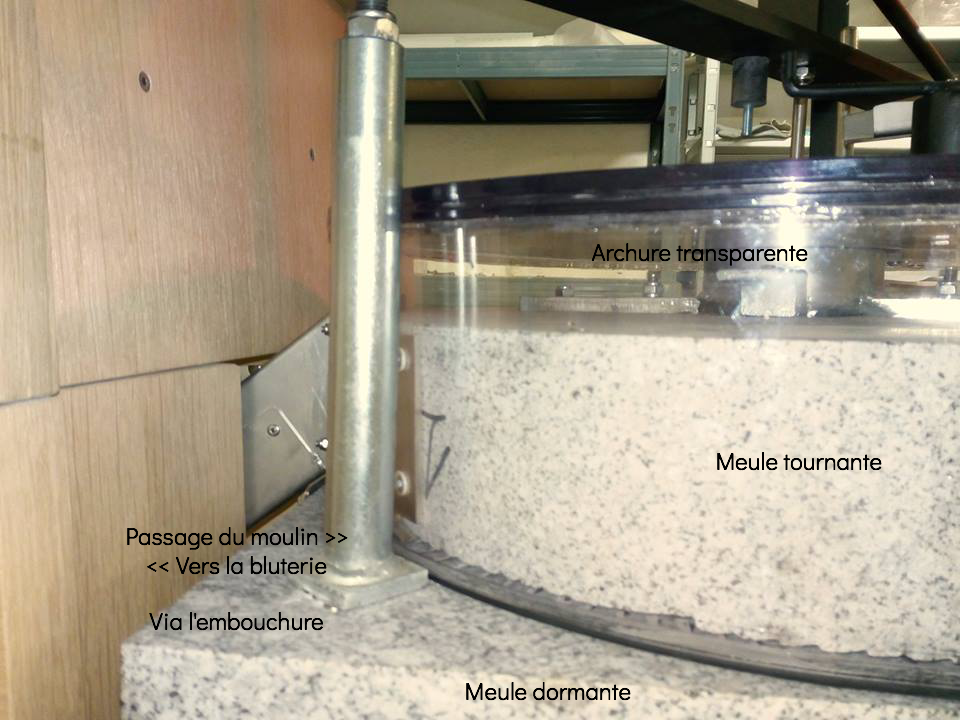

The hopper sits on top of the arch (the system that surrounds the grinding wheels). These components can be dismantled quickly and easily if required.

And where does the bluterie fit into all this?

Once the cereal has been unrolled, it is pushed at the ends by the rotation of the rotating grinding wheel. It is then pushed naturally through a mouthpiece into the sifting mill.

It is then gently placed in a sieve (supplied with your mill). This sieve rotates constantly, depositing your flour at the bottom of the sieve mill and removing the bran with each rotation.

En fonction du type de farine que vous souhaitez produire, vous pouvez opter pour plusieurs tamis qui peuvent être changés en un clin d’œil, de sorte que votre farine au fond du moulin à tamis sera différente.

So how does an Astrié mill work?

We have written an article on ‘Everything you need to know about the Astrié mill’.

‘The mill is made up of a fixed lower stone wheel (known as the dormant wheel) and a rotating upper wheel. The upper millstone has a hole in the middle to allow the grain to pass through.

The rotation of the millstone gradually moves the grain from the centre to the periphery, crushing it little by little, before the surfaces, which become closer and softer, lead to the unbroken husks sliding off.

During the same operation, all the substances released are intimately mixed, including the germ, despite its slightly oily and tough consistency.