The ash content was developed for cylinder milling.

The higher the ash content, the higher the mineral content of the flour, i.e. the bran (the husk of the grain).

This standard is of little relevance on stone millstones or Astrié millstones, since in a single pass the whole grain of wheat is in the flour. And obviously, this will differ from year to year. So the flour will not have the same quantity of minerals depending on the year, depending on the plot of land… And this explains the variations in wine, the vintages…

So we keep that in mind, but it’s important to understand that the specificity of the Astrié milling process is that it works in a single pass, so we have a product that is a product of the terroir, a product that is as regular as the harvest, but which will have its own properties (depending on the climate, the plot of land…).

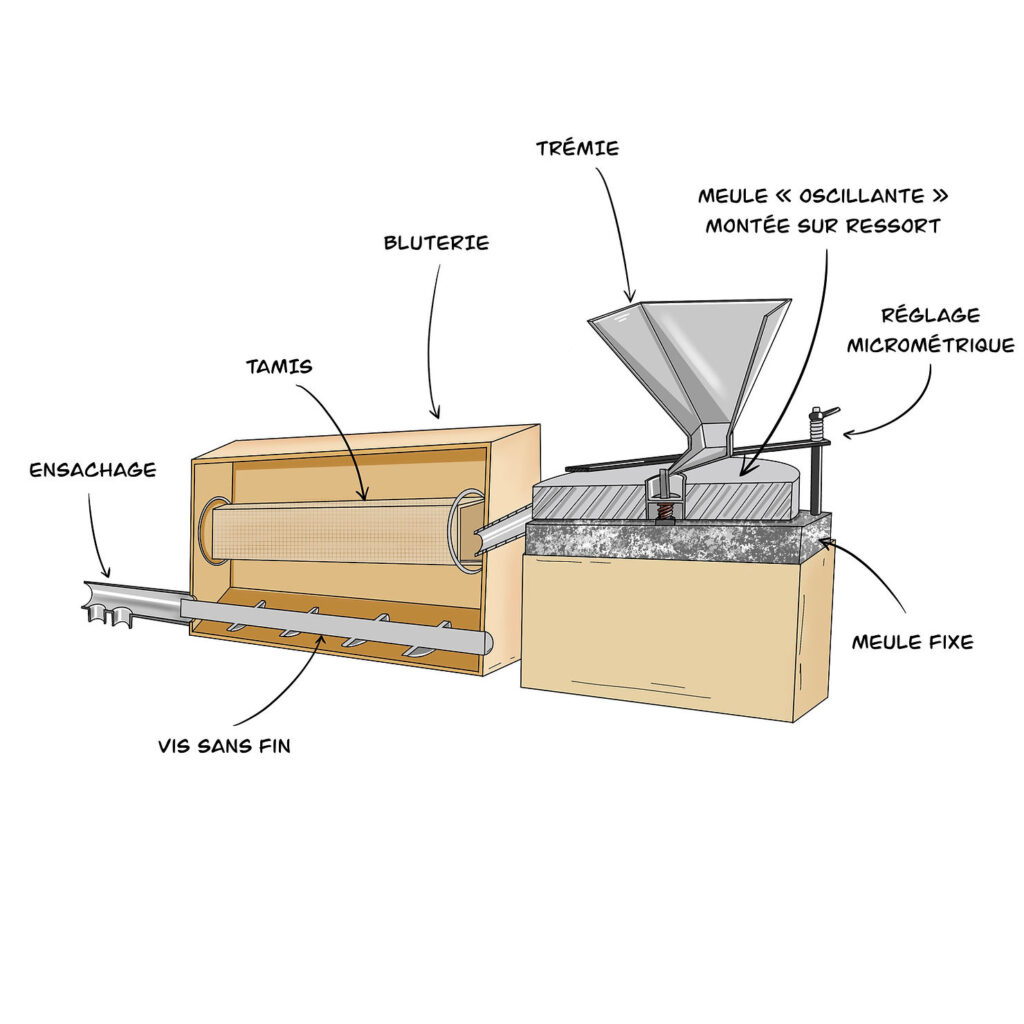

So what are the sieves on an Astrié mill?

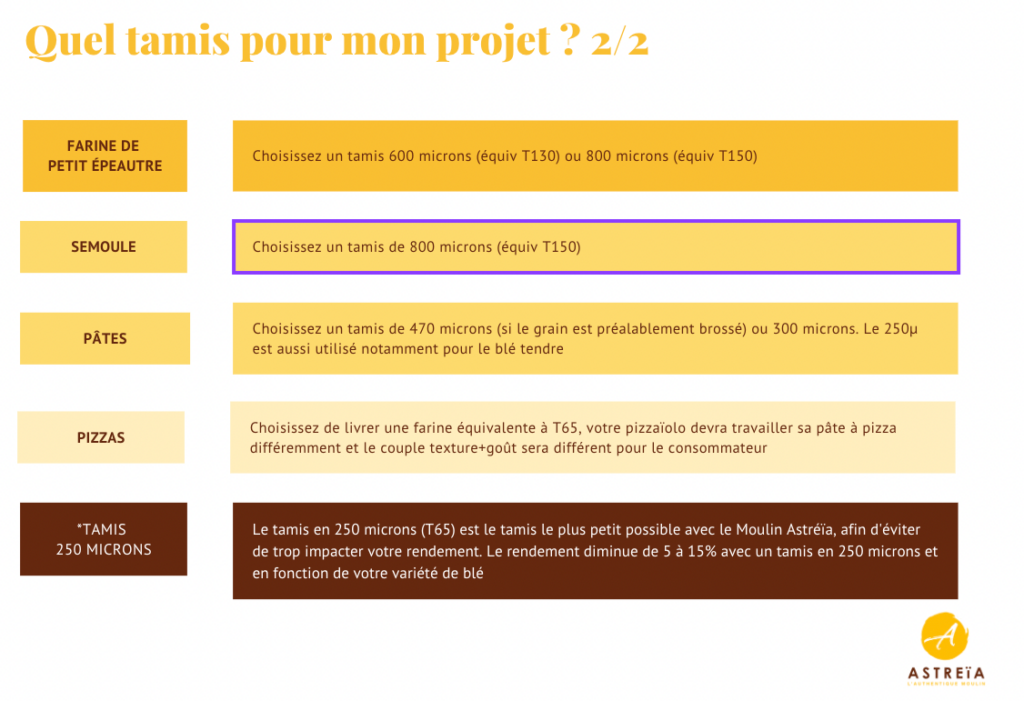

Astreia sieves have different mesh openings to allow more or less bran to pass through into the flour.

The larger the mesh opening, the higher the ash content and the more bran will pass through. The result is wholemeal flour.

- Sieves with 800 micron mesh could correspond to T150 flour, wholemeal flour

- 600 micron sieve could be used for T130 wholemeal flour

- 470 micron sieve could be used for T110 flour

- 300 micron sieve could be used for T80 flour

That’s why, for each sieve, we talk in terms of ash content equivalence, because it’s a known standard, but it is indeed an equivalent. We also talk a lot about this standard with wheat grains, but you need to be aware that with other cereals (small spelt, buckwheat…) you need to be careful about the rise of the bread and the choice of sieve (while maintaining the maximum output of the mill).