If you only have 2 minutes to spare, here’s a summary:

- An industrial cylinder mill makes a lot of flour very quickly. The grain is oxidised, permanently altering the nutritional value of your flour.

- A traditional stone mill crushes the grain slowly, giving a better quality grind and a more pronounced flavour, but the crushing process breaks the starch-gluten bonds, making it impossible to produce a flour that is sufficiently digestible and has high added value. The flour has to be pressed several times before it is ready, which means that it has to be handled and attended to more frequently.

- An Astrié stone mill unrolls the grain (no ironing and 80% extraction rate in a single pass) to obtain the best quality flour at every level (flour work, sweetness, nutritional quality, etc.).

To do this, it’s essential to take a step back to gain perspective and understand the raw material.

Contents

1) Professional Cylinder Flour Mill

Principle

Action on the wheat and therefore results on the flour

Output

2) Traditional stone flour mill

Principle of this flour mill

Action on the wheat

Be cautious about added value

Choosing a manufacturer and not an assembler: how to make sense of it all?

3) Astrié-type stone flour mill

Principle of the Astrié type stone flour mill

Action on the wheat

Why do we talk about exceptional flour?

How do you choose your manufacturer?

Which mill is best suited to my project?

As a reminder, what is a grain of wheat made of?

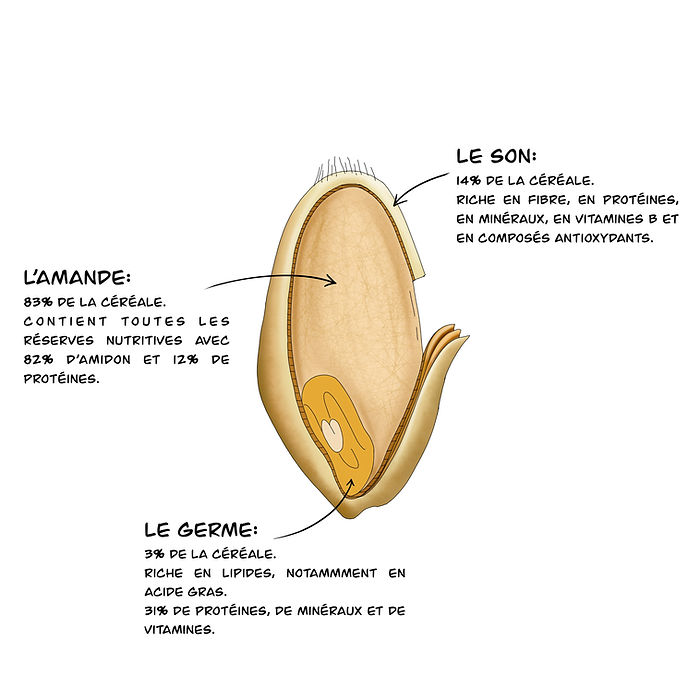

The grain of wheat is composed as follows

- the base of the wheat kernel: this is where the germ lies

- in the middle, the kernel

- on the outside, the husk (what surrounds the kernel)

What does each part of the grain of wheat represent?

- the germ of the grain accounts for between 2 and 3% of the total

- the kernel represents about 78

- the husk accounts for around 20% of the total

What’s in each part of the grain of wheat?

- the germ of the grain represents between 2 and 3%: contains all the vitamins and amino acids

- the kernel accounts for around 78%: contains gluten and starch

- the husk accounts for around 20%: the protein base of the grain is located on the reverse side of the husk. This is important for better bread leavening and bread-making in general.

Cylinder mill

How does it work?

The wheat grain passes between rollers to be crushed. The cylinders are spread apart to varying degrees. What comes out of this crushing (the milling waste) is sifted. The milling waste is then passed between two more cylinders, sieved, and so on up to 7 or 8 times, depending on the mill. This is known as a grinding diagram.

Action on the grain of wheat: what is the aim of the operation?

The wheat kernel is peeled from the outside, moving closer and closer to the heart of the kernel. The closer we get to the heart of the wheat kernel, the more the kernel is trimmed, and the whiter the flour, but the higher the gluten content.

The germ is removed for two reasons:

- it gives a fatter consistency to the flour. If the flour is too fatty, it must be consumed within 6 to 12 months, whereas with a less fatty flour, millers who produce very large volumes of flour can keep it for several years without the flour going rancid.

- the germ is sold to the pharmaceutical industry to be used as a dietary supplement (ironically, since the germ is extracted from the flour and is therefore no longer present in it, so that it can be consumed as a dietary supplement in flour that is too low in fat!)

The famous ‘ash ratio’ T80, T110….

Each time the milled flour is sieved, we are able to separate the elements methodically: on the one hand, the husk (the bran), the germ and the kernel. The result is a flour with a high bran content. These are the famous ‘T’ flours: T80/T110/T130/T45.

They have a gluten and starch base and depending on the ‘T’ (ash content) there will be more or less ‘bran’. Schematically.

The grain passes through the rolling mills once, then it is sieved, the flour is pitted and the rest is pressed, semolina… so we have to pass through the rolling mills again, once, twice, three times (…) until we get to the kernel.

This cylinder mill produces flours that have more or less incorporated the husk of the wheat grain (the bran). But never the germ.

So we’re going to have flours that are more or less white:

- very white flour: the heart of the wheat kernel (T45), known as groat flour

- rich flour: there is a lot of grain husk (T150), we are at the very beginning of the kernel, a so-called wholemeal flour

This system allows us to produce very distinctive, highly classified flours.

But they are simply blends with more or less gluten or starch and more or less bran. But flours cannot reflect the entire grain of wheat.

In a nutshell

Cylinder milling gives very high yields (kilos of flour per hour) because they run at full speed. It is therefore not comparable with stone mills.

Flour is highly graded to meet a highly standardised demand from the bakery and biscuit industries (agri-food).

The flour is very hot and oxidised as it passes between the rolling mills, and pneumatic transport of the flour adds further oxidation to the basic roller mill process.

Flour is not nutritious and therefore obviously not easily digestible, because flour is just an assembly, a concentrate of starch and gluten. If, in addition, the basic wheat grain is not of good quality, or if the wheat has been modified to concentrate more gluten, this only makes the process of concentrating the gluten in the flour worse.

Gluten makes it possible to mechanise dough for baking to the maximum, so high gluten concentration is expected by the baking industry regardless of the health consequences for the consumer and for the baker who handles them.

The germ and bran (the protein base) are removed, so we inevitably have a gluten concentrate, which is sometimes even corrected by adding even more gluten to encourage industrial bread-making.

Traditional stone mill

What is the principle behind the traditional grinding mill?

We have a ‘flying’ stone millstone that crushes the wheat grain because of its weight.

The best proof that this crushes the grain is that the ‘semolina’ has to be passed through the mill again to make flour and achieve the 80% extraction rate.

You have to pass the wheat several times between the millstones to extract 80% of the grain! Remember, the remaining 20% represents the ‘bran’ (the husk of the grain).

What influence does this have on the mill’s output? Be careful!

It is often advertised as 30 kilos per hour. But be careful, is that 30 kilos of flour or wheat? Word games are often important.

A mill produces flour, not wheat! So you need to know the yield expressed in KILOS OF FLOUR and not wheat, which is nonsense.

Next, the 80% extraction rate would allow us to make 80 kilos of flour from 100 kilos of wheat. Except, remember, there’s ironing involved here. So out of the 80 kilos that supposedly come out of the mill, there are not 80 kilos of flour, but part of it has to go back through the mill to produce flour (and not semolina). This inevitably has an impact on the output per hour, as it has to be passed through the mill again to produce flour. Sometimes this has to be done 2 or 3 times. Sometimes you need to have someone available to do this, or have a traditional stone mill that transports the material to the mill for ironing. With pneumatic transport of the material (sound familiar?).

In short, in terms of output: you end up with around 30 kilos of flour per hour maximum.

Influence on flour quality

Logically, the more the grain, semolina or other material passes back and forth between the millstones, the more it is heated and oxidised.

If the material is automatically returned to the mill with pneumatic transport (as on a cylinder mill), there is additional oxidation.

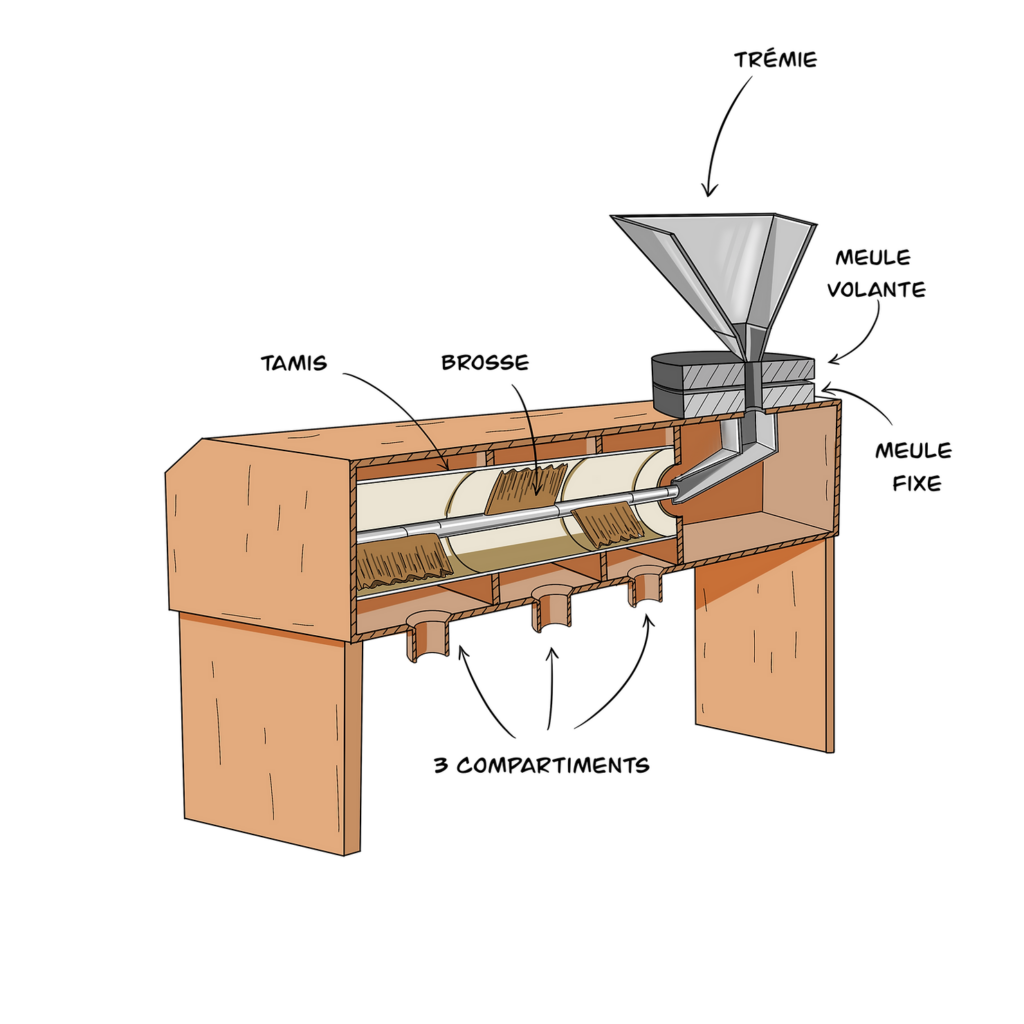

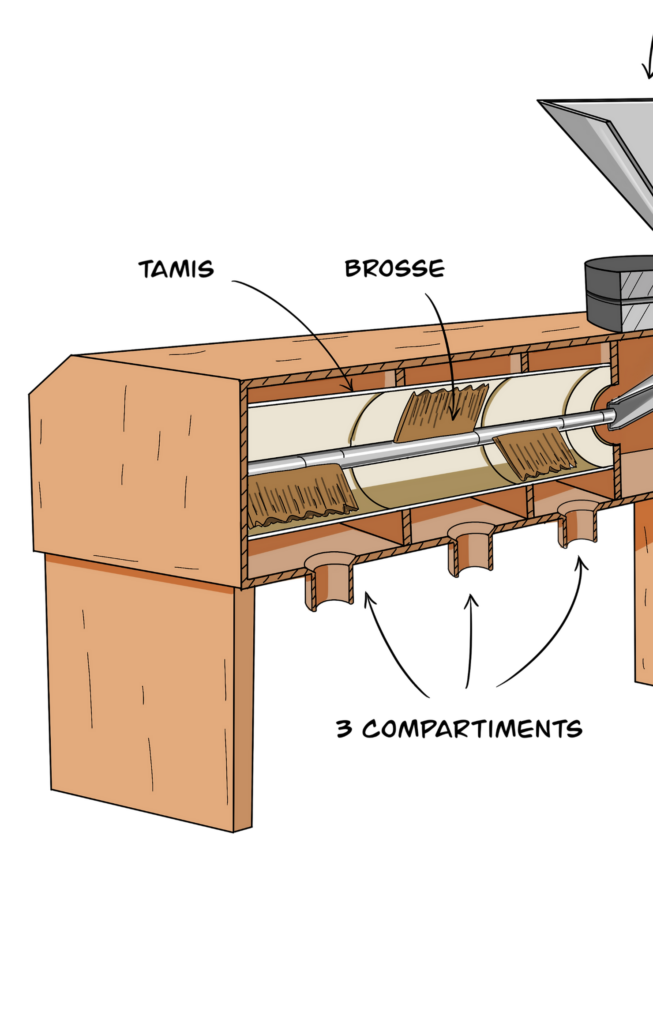

Sieving

- On a traditional stone mill, the sieving process is carried out by brushes that force the grindings through the cloth. The cloth must be changed regularly.

- This ‘forced’ passage makes the flour more pitted, as the bran is forced to pass between the meshes.

- A solution often devised by certain manufacturers (Tyrol, for example) is to divide the sifting machine into 3 parts. In this way, the whitest flour is found in the first third of the sifting chamber, in the middle of the sifting chamber the flour is more pitted and in the last third the flour is very pitted (more bran present, therefore higher ash content).

This could allow a T80 at the beginning of the bluttery, a T110 in the middle of the bluttery and a T130 at the end of the bluttery.

Please note! Remember that the ‘ash ratio’ system was invented for the operation of the roller mill, which is not the example to follow in terms of nutrition or flour digestibility. So using this idea on a stone mill would mean that we’re doing the same thing to the grain of wheat, when the idea is really, on the contrary, not to do the same thing!

Remember too, what we really want is to preserve the germ of the wheat grain, but in this case of a sifting mill divided into 3 compartments, the germ will only be present in the first third of the sifting mill. In the whitest flour, not in the other flours, which will therefore be of poorer quality.

So if we divide our sieving machine into 3 parts, and force the milling results through the sieve cloth with the brushes, we’ll have: a nutritious part with the germ in the first third and then a flour similar to what we can get with cylinder milling but… without the yield!

Influence on the arm’s length relationship with the manufacturer and reseller

You’ll need to make sure that you have a good after-sales service for all the mechanical and electronic parts, and that you allow for normal wear and tear over time, but factor this into your budget.

Be careful, too, because this type of mill is often not sold by the manufacturer but by a retailer or a company that assembles or has assembled various parts of your mill.

There is therefore a middleman, and it is strongly recommended that you check the terms and conditions of the after-sales service and warranties between the retailer and the actual manufacturer, as well as their geographical location (in Europe? Abroad?)…

Also beware of ‘manufacturers’ who actually assemble certain parts of a mill and add others. Make sure you know who provides what (in terms of after-sales service) before you buy, and how quickly after-sales service can or cannot be provided. In addition, of course, to the fact that the assembly of all or part of the mill often raises the question of the coherence of the whole.

Stone mill known as Astrié

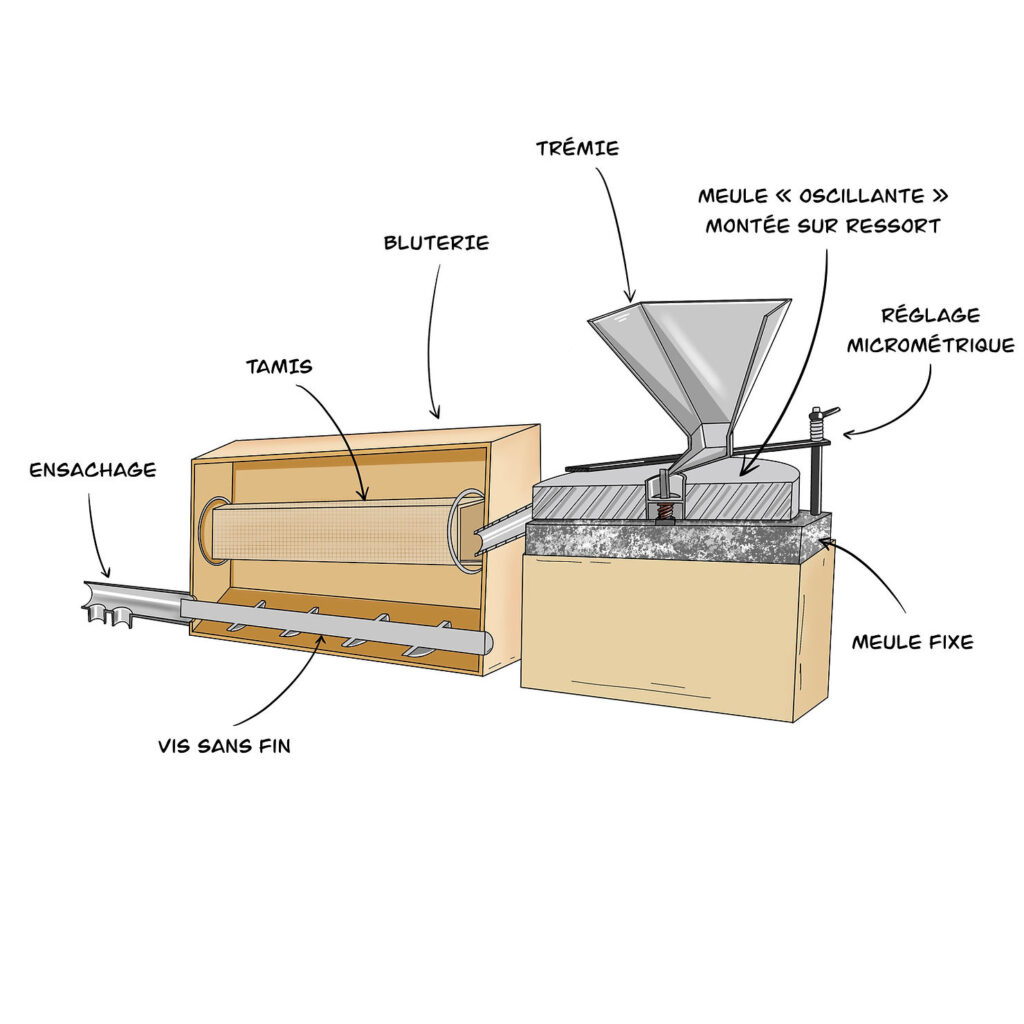

How does it work?

There are also stone millstones here, but the rotating millstone does not crush the grain by its weight, but unrolls it.

How does unrolling change everything?

So there’s no need to pass the grain several times between the millstones, as the 80% extraction rate is achieved in a single pass. So all the wheat grain is present in the flour and the sifting process extracts the bran (the husk of the wheat grain, which represents the remaining 20%).

It is this oscillating millstone (it is on a spring so as not to crush the grain) and the micrometric adjustment between the millstones that makes this mill an Astrié mill (named after their inventors Pierre and André Astrié).

These two elements, combined and consistent with each other, make it possible to free oneself from the weight of the millstone and adapt to the flow of grain that will arrive between the millstones.

Influence on mill output: all in one go!

With an Astrié mill, the extraction rate is achieved in a single pass, so there’s no need to run the semolina through the mill again, and no need for human intervention. The wheat grains pass through the mill and the flour comes out in one go, directly.

Influence on flour quality

Astrié flour is no more and no less than the exact reflection of the grain.

Sieving

On an Astrié mill, you have a sieve that is stored in the bluttery (the wooden box that holds your flour). The sifting is carried out using tapotins, which are not in contact with the flour, but simply create a gentle vibration that gently loosens the flour through the sieve cloth.

There is no need to change the quality of the flour according to the desired ash content. You simply change the sieve, and by changing the sieve (the mesh is more or less tight) you can change the ash content without changing the quality of the flour!

Influence on the farmer’s autonomy

With an Astrié mill, you’re using a LowTech product with little (if any) on-board technology, making it easy to understand the coherence and operation of the product from start to finish. Everything is visible and accessible to everyone. So you have a product in your hands that is built to last and that you can handle easily. The parts that make it up are simple, readily available and easy to change. The sensors are mechanical and repairable.

Manufacturer and only Manufacturer : Astrié

Whichever Astrié mill manufacturer you choose, you are in direct contact with the craftsman who makes your mill ‘before your eyes’. There are no Astrié mill dealers anywhere in the world today.

This human link allows you to be sure of the quality of the manufacture, but also of the follow-up and after-sales service. Even if no one wants to think about it, it’s imperative to know its limits, availability, reactivation and possibilities before you buy.

What’s more, you’ll be meeting people who have real expertise in the field, because the manufacturers of Astrié mills are generally farmers themselves, or even bakers. This is the case with Astréia, since JM Ximena is both a farmer and a baker, so he has his own land and his own bakery, and he is perfectly capable of understanding your problems in the field to find reliable and consistent solutions for you over time.

We have also created a guide for all professionals who want to start producing flour with an Astrié Stone Flour Mill: you can read it here